Description

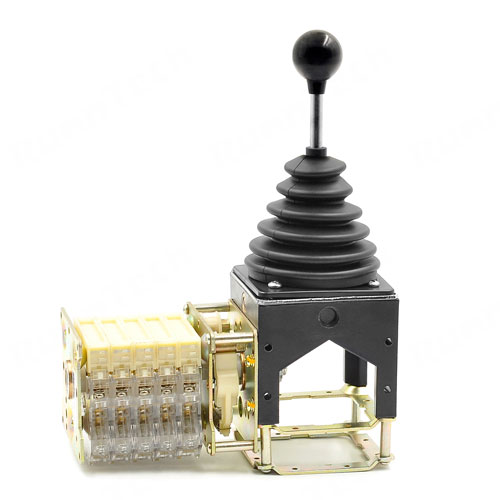

RunnTech 300 series industrial crane & hoist joystick (master controller) is mainly used in the crane and hoist operations. It is primarily designed for use in circuits with AC 50Hz (60Hz) and rated voltage of 380V or below. It enables motor operations including reversing, speed regulation, braking, synchronized control and split control. It has been widely adopted across port operations, maritime systems, railway infrastructure, metallurgy, mining, power facilities, construction equipment and industrial machinery manufacturing sectors..

Crane & Hoist Joystick Controller Gallery

HD39 grip single axis, I type (lift to release)

HD39 grip dual axis, I type (lift to release)

HD39 grip single axis, L type (lift to release)

HD39 grip dual axis, L type (lift to release)

HD2 grip single axis, I type

HD2 grip dual axis, I type

HD2 grip single axis, L type

HD2 grip dual axis, L type

HD7 grip single axis with 1 pushbutton, I type

HD7 grip dual axis with 1 pushbutton, I type

HD7 grip single axis with 1 pushbutton, L type

HD7 grip dual axis with 1 pushbutton, L type

HD8 grip single axis, I type

HD8 grip dual axis, I type

HD8 grip dual axis, L type

HD10 grip dual axis, with deadman and front max. with 6 pushbuttons

HD5 grip single axis, I type (lift to release)

HD5 grip single axis, L type (lift to release)

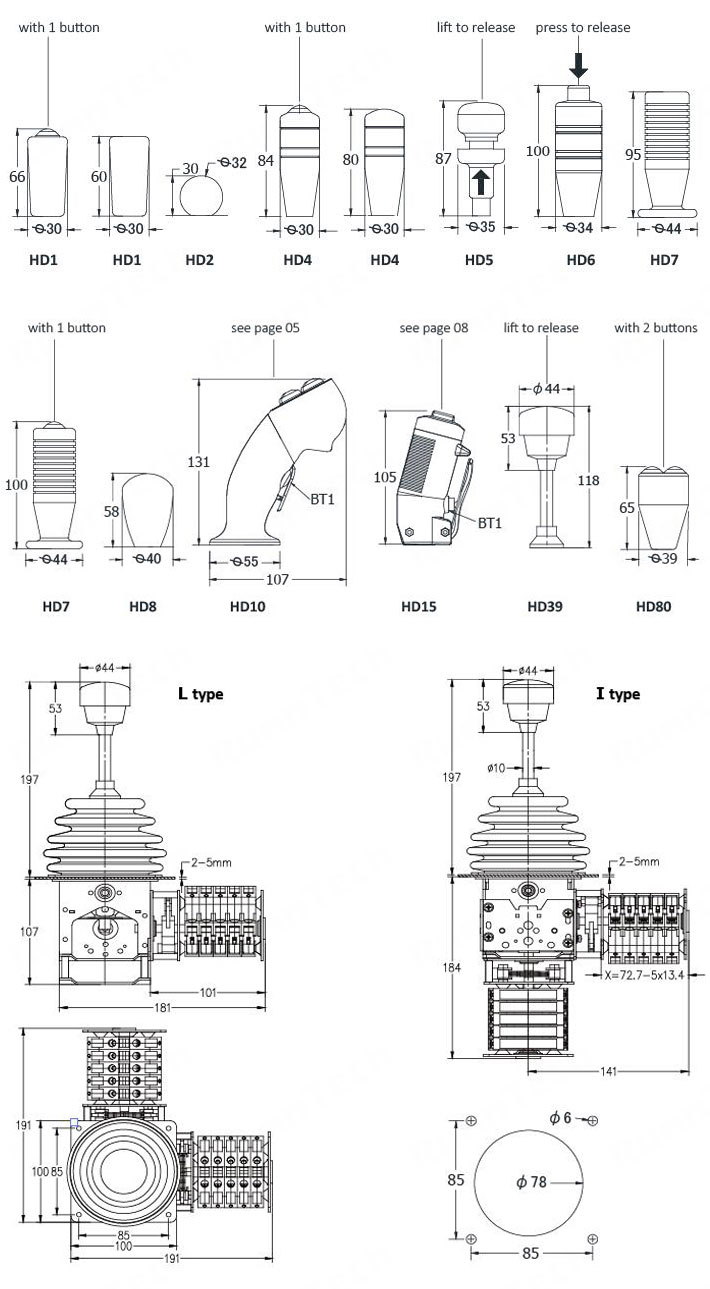

RT300 Crane & Hoist Joystick Controller Diagram